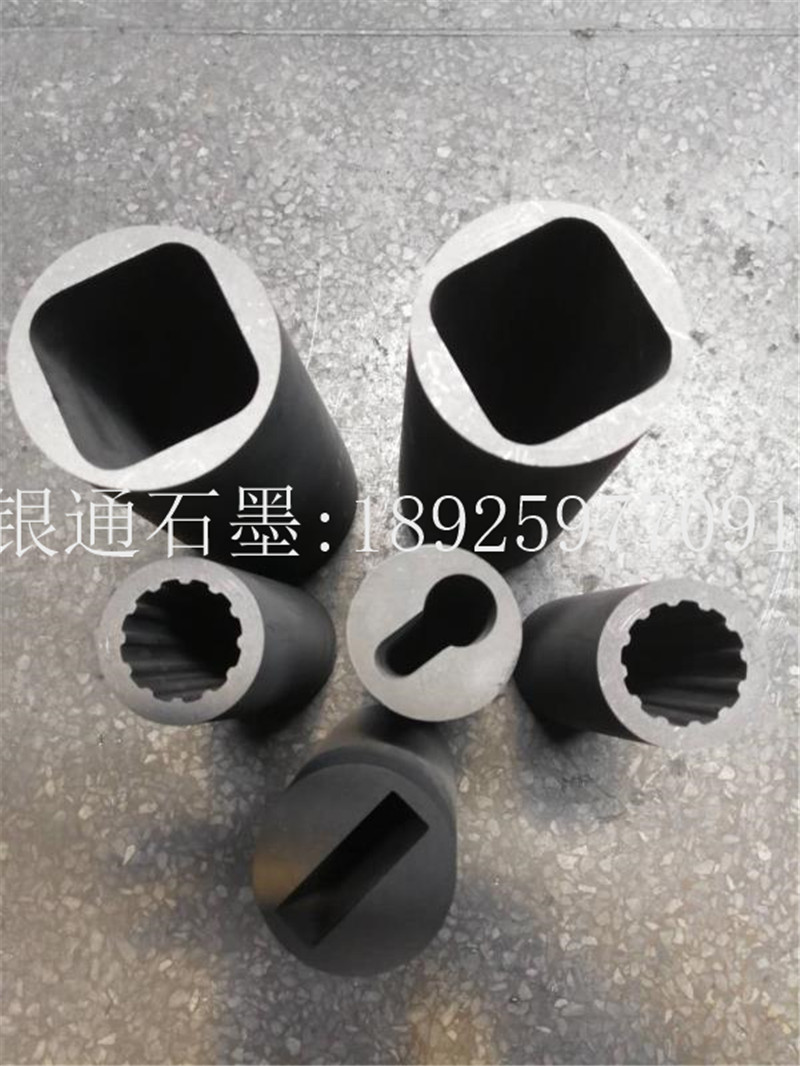

In the past, copper was widely used as electrode material in EDM. With the rise of copper price and the progress of graphite technology, the price of graphite material is decreasing, so graphite is more and more widely used as electrode material for EDM. What are the advantages of graphite material processing?

1. Good machinability

The cutting resistance of graphite material is small, and its machining efficiency is about two to three times that of copper.

2. Outstanding effect of electrical discharge roughing

The melting point of copper is 1083 ℃, and the temperature at the moment of discharge can reach 1100 ℃. The copper electrode is easy to wear, while the graphite will sublimate at 3550 ℃. Therefore, the graphite electrode is more vulnerable to high current, and can complete the electrode consumption.

3. It is easy to realize the processing of thin rib style

The copper electrode produced by cutting heat is easy to produce thermal deformation. Because of the plastic property of the material, the elastic deformation will easily occur when processing the thin rib style, causing the processing vibration. The graphite itself is made of sintered particles, and its characteristics of heat-resistant and brittle material can reduce the processing deformation and vibration.

4. Smaller thermal expansion

The thermal expansion rate of graphite is 1 / 4 of that of copper, which can effectively reduce the deviation caused by heating deformation of electrode.

5. Lighter weight

The density of graphite is only 1 / 5 of that of copper, which can effectively reduce the burden of machine tool (EDM) when large electrode is used for EDM, and it is more suitable for application in large mold.

6. No burr

After the copper electrode is processed, it needs to be manually trimmed to remove the burr, while the graphite has no burr after processing, which saves a lot of cost and makes it easier to realize automatic production.

7. Faster processing speed

Under normal circumstances, the machining speed of graphite is 2 ~ 5 times faster than that of copper; while the EDM speed is 2 ~ 3 times faster than that of copper, the material is more difficult to deform: it has obvious advantages in the processing of thin rib electrode; the softening point of copper is about 1000 degrees, which is easy to deform due to heat; the sublimation temperature of graphite is 3650 degrees; the coefficient of thermal expansion is only 1 / 30 of copper.

8. Lower discharge consumption

Because the spark oil also contains C atoms, the high temperature causes the C atoms in the spark oil to be decomposed and form a protective film on the surface of the graphite electrode to compensate the loss of the graphite electrode.

9. Easier to grind and Polish

As the cutting resistance of graphite is only 1 / 5 of that of copper, it is easier to grind and polish by hand.

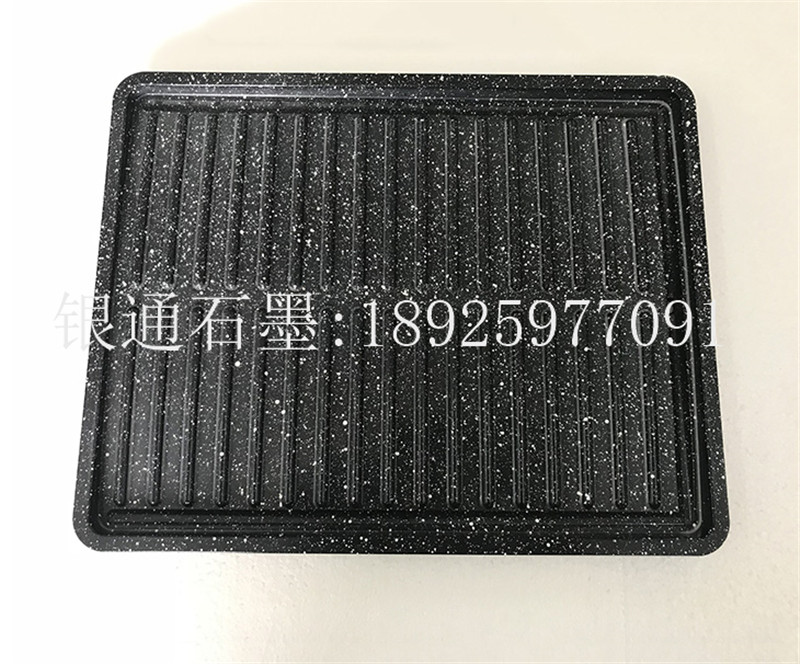

The advantages of graphite material processing are shared here, but the processing of graphite materials requires graphite machine. Graphite machine is a common processing center in the market, which is widely used in the fields of automobile, machinery and hardware.

客服1

客服1